Categories Gearboxes

Gearboxes

Your products on GBX and CP2 rotate continuously and forced because of a rotation mechanism. This delivers the highest and reliable rotation around the third axle. GBX and CP2 are compatible with COLT plates, which means both can be stacked together on the same tower.

All GBX and CP2 are provided with an overload clutch. The clutch disconnects the gearbox if it is e.g. blocked by whatever reason. In the usage of many gearboxes, you safe the whole charge, by only losing the parts of the defect gearbox. With GBX and CP2 gearboxes, the actual gearbox is usually encapsulated in a casing. This can easily be dismantled and given away for blasting or stripping. With the cover removed, the gearboxes can be easily serviced.

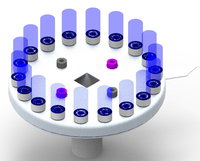

The most important dimensions of the gearboxes for you are shown in the schematic product image:

- Outside diameter (OD) of the gearbox housing: It must be OD ≤ dp (planet diameter). The value of OD always appears in the designation behind the word “gearbox”.

- Distance (S1 - S2) between adjacent substrate axes: It must be (S1 - S2)> ds + a (substrate diameter + distance).

- Partial circle diameter (PCD) of the hubs: It must be PCD + ds <dp.

- Planet shaft dimensions: This must match your planet shafts. The dimension of the planet shaft is always in the name after the division T.

Click on the image to open the list of available gearboxes. Yo can filter the list according to your machine / products.

We offer various forms of interfaces to your products. The last group of characters in the gear unit designation describes the form of the hub. The simplest form is the rotating pin (P). Substrates can be placed quickly and at any angle. The thread (M) offers more stability. The products are firmly connected to the hub but putting them on is more complex. If the substrates are stored again at the upper end, the rotation below must be guaranteed e.g. by a wedge-shaped hub (W).Finally, there are magnetic recordings (Mag). The last digit in the name indicates the diameter of the hub.

The gearbox types are sorted into five weight classes and in a special catalog for gearboxes with magnetic hubs. When leafing through, we recommend changing the sorting order in the catalog to "Name". The gears are then sorted from small to large and from a few positions to many.

CP2 Gearboxes

CP2 gearboxes combine a planetary transmission with a reduction transmission. For smaller substrates the gears unde the substrate bushings must become small as well in order to acheive a high capacity. With this the rotation speed of the substrates may become too high. A standard gearbos of OD Ø130mm with 24 positions increases the rotation speed of the substrates by factor 8. In case the planets themselves rotate at 15 min-1 the substrates will reach 120 min-1. This requires a lot of power and will create wear and particles. Smaller substrates may even fall off the fixtures.

Light Gearboxes

Light Gearboxes are made for small and light substrates. The light gearboxes are more compact and of less weight compared to medium or heavy gearboxes. But the load per pin is also limited to about 250g. Light gearboxes usually come with an exchangeable cover. The number of pins on a Ø130mm OD light gearbox is limited to 24.

Medium Gearboxes

Medium Gearboxes are made for middle weight substrates. The medium gearboxes are slghtly bigger and of less weight compared to medium or heavy gearboxes. But the load per pin is limited to about 500g. Medium gearboxes come with or without an exchangeable cover. The number of pins on a Ø130mm OD light gearbox is limited to 16.

Heavy Gearboxes

Heavy gearboxes are more solid and can carry larger loads.

The payload per position is up to 4kg. Heavy gearboxes are mostly intended for V20 planetary shafts.

They are available with or without a removable housing.

Extra heavy Gearboxes

Heavy Duty (HD) gearboxes are made for the highest loads. Up to 15 KGS per pin is possible. You will find these gearboxes usually on substrate carousels with bigger (>178mm) planets. HD gearboxes can be operated with upper bearing plate in order to stack substrates to a total height of up to 1500mm.

Gearboxes with magnet pins

In addition to the form-fit, there are also force-fit holder with magnets. Smaller parts hold with a single magnet, heavier parts on a yoke with multiple magnets. The magnets are made of SmCo and can be used up to approx. 300 °C. In addition to the magnetic recordings, covers should be put on, which on the one hand protect the holding and on the other hand center the products and create a clean transition between masking and coating.